What is Cardboard Recycling?

What is Cardboard Recycling?

Cardboard, also referred to as corrugated cardboard, is a recyclable material that is recycled by small and large scale businesses to save money on waste disposal costs. Cardboard recycling is the reprocessing and reuse of thick sheets or stiff multilayered papers that have been used, discarded or regarded as waste.

Step-by-Step Process of Cardboard Recycling

1. Collection

“Collection” is the first step in recycling cardboard. Recyclers and businesses collect the waste cardboard at designated cardboard collection points.

The majority of the collection points include trash bins, stores, scrapyards, and commercial outlets that generate cardboard waste. After collection, they are then measured and hauled to recycling facilities, mostly paper mills.

At this point, there are certain types of cardboard that are accepted, while some are not depending on how they were used or manufactured. For instance, cardboard that is waxed and coated or used for food packaging are not accepted in most cases as they undergo different specialized recycling process.

2. Sorting

Once the corrugated boxes arrive at the recycling facility, they are sorted according to the materials they are made of. In most cases, they are classified into corrugated cardboard and boxboard. Boxboards are the ones that are thin such as those used for cardboard drink containers or cereals boxes.

Corrugated boxes are bigger and stiffer commonly used for packaging transport goods. Sorting is important since paper mills manufacture different grades of materials based on the materials being recovered.

3. Shredding and Pulping

After sorting is done, the next step is shredding, and then pulping follows. Shredding is done to break down the cardboard paper fibers into minute pieces. Once the material is finely shredded into pieces, it is mixed with water and chemicals to break down the paper fibers that turn it into a slurry substance.

This process is what is termed as pulping. The pulped material is then blended with new pulp, generally from wood chips, that ultimately help the resulting substance to solidify and become firmer.

4. Filtering, Conterminal Removal, and De-Inking

The pulp material is then taken through a comprehensive filtering process to get rid of all the foreign materials present as well as impurities such as strings, tape or glue.

The pulp further goes into a chamber where contaminants like plastics and metals staples are removed through a centrifuge-like process. Plastics float on top while the heavy metal staples fall to the bottom, after which they are eliminated.

The next process, de-inking, involves putting the pulp in a floatation device made up of chemicals that take away any form of dyes or ink via a series of filtering and screening. This step is also called the cleaning process as it cleans the pulp thoroughly to ensure it is ready for the final processing stage.

5. Finishing for Reuse

At this stage, the cleaned pulp is blended with new production materials after which, it is put to dry on a flat conveyor belt and heated cylindrical surfaces.

As the pulp dries, it is passed through an automated machine that press out excess water and facilitates the formation of long rolls of a solid sheet from the fibers called linerboards and mediums. The linerboards are glued together, layer by layer, to make a new piece of cardboard.

In other cases, the medium is used as the corrugated sheet, which is taken through two huge metal rolls with teeth to give it the ridges. Linerboards are then glued to the medium as the thin outer covering.

Alternatively, the linerboards and mediums are ferried to boxboard manufacturers, where the manufacturing process is completed by the use of machines that shape and create a crease along pattern folds to make the boxes used for packaging or transporting products.

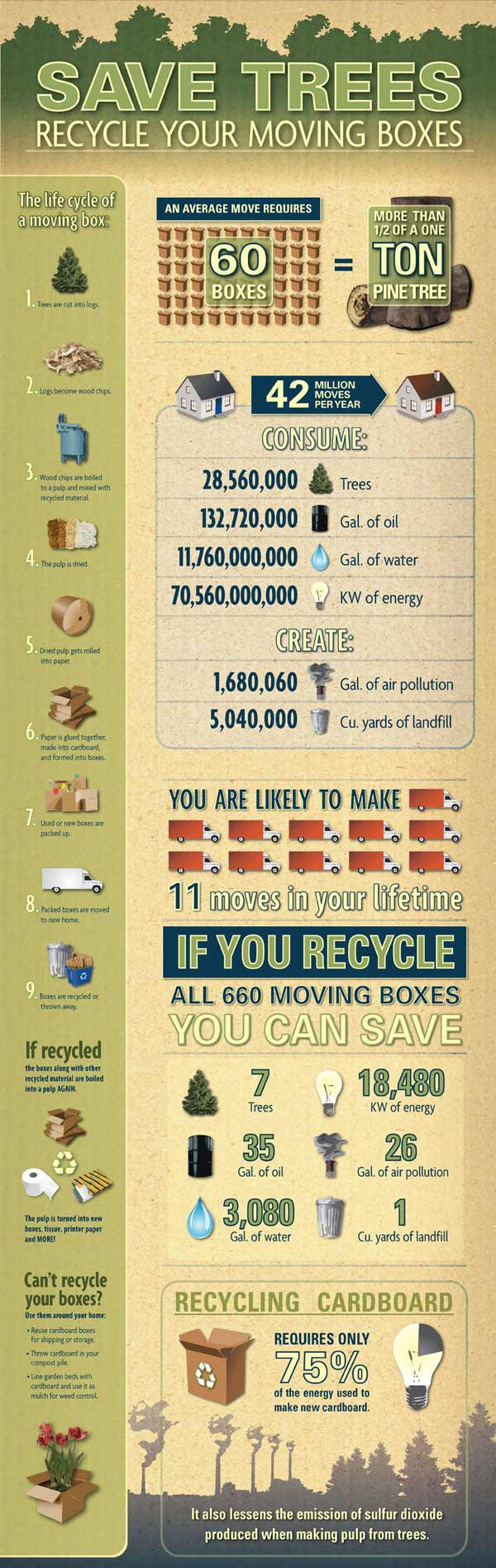

Saves Energy

Owing to the highest percentage of cardboard recyclability, the amount of energy required for producing corrugated packing products is tremendously reduced, and the saved energy can be used in the manufacture of other resources.

Recycling cardboard requires only 75% of the energy required to make new cardboard. Recycling of cardboard requires 90% less water and 50% less electricity needed to make them.

Box-N-Out Baler Program

Does your business frequently find itself swimming in cardboard and packing foam? Is it becoming more and more cumbersome with every product shipment to flatten and dispose of the cardboard? Is Polystyrene White Foam filling up your dumpster? Would your staff’s productivity increase if your business had its own baler and customized solution for foam?

Box N Out can help with its unique Baler Program. Click the Act Now button below, fill out the simple form, and one of our Commercial Baler Consultants will contact you to customize a Baler Program that best meets your business’s needs

Questions About Baler Recycling?